Here at West Coast Suspensions we are able to custom manufacture U-Bolts. You can bring us a sample U-Bolt or download our Custom U-Bolt order form and complete the fields:

Here at West Coast Suspensions we are able to custom manufacture U-Bolts. You can bring us a sample U-Bolt or download our Custom U-Bolt order form and complete the fields:

- Material Diameter (D)

- Inside width (B)

- Inside length (L)

- Form Type (Shape)

Using these measurements we are able to custom manufacture U-bolts by cold forming them on our U-Bolt bender, in most cases while you wait.

If the U-bolts required have a forged Length (PL – squashed flat) we may be able to reproduce them although a sample would be required. Forged U-Bolts necessitate an extended manufacturing timeframe due to the steps required in the forging process.

We carry a range of U-Bolt studs in diameters from 7/16″ all the way up to 1 1/4″ imperial UNF in various lengths. These vary in material grade from 7/16″ Grade 2 up to 11/4″ Grade 8.

All of our custom U-Bolt threaded rods have a rolled threaded. The cold-worked process of rolling threads often strengthens the material by up to 30%. Threads produced through rolling also typically exhibit 50-75% greater fatigue strength, as the process eliminates potential surface imperfections that could lead to fatigue failure.

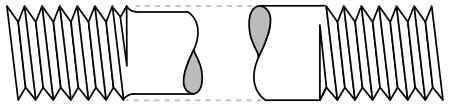

Always ensure the diameter is measured on the thread as the shank size varies depending on if the thread is rolled vs cut.

Rolled Thread (left), Cut Thread (right)

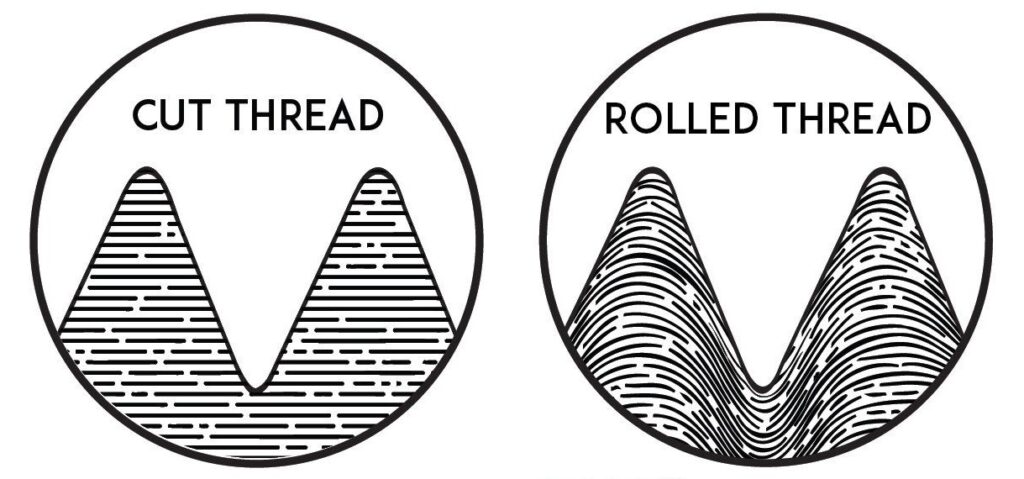

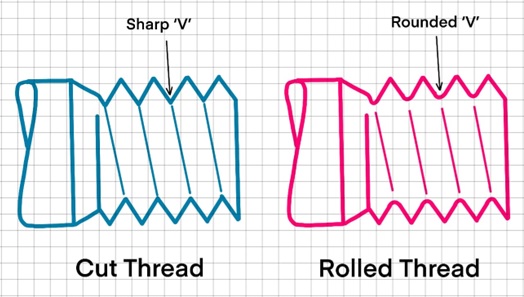

The key differences between a cut and a rolled thread are; a cut thread, also referred to as a machined thread, is created by removing material from a stud, bolt or screw to create the threads. This process is typically done using a single point tool, threaded dies, thread mills or a tap to achieve the desired thread diameter and pitch. As material is removed from the stock, this process can weaken the core body of the respective stud, bolt or screw.

On the other hand, a rolled thread is produced by pressing the thread form into the stud, bolt or screw by passing a bar or blank through flat plates, round dies and other forming tools. This method does not remove any material from the stock.

Advantages of a Rolled Thread

The key advantage to a rolled thread over a cut thread is the enhanced fatigue properties. Due to the nature of the thread being pressed into the body and the manufacturing tooling associated in that production method, a rolled thread will have a rad in the root of the thread.

In comparison to a cut thread which will have a sharp ‘V’ cut at the root of the thread, the additional radii in a rolled thread allows for much better load transfer under cyclic loading.

This root radii also increases the bolts cross sectional area compared to a cut thread making a rolled thread slightly stronger in tensile loading as well!

During the forming of a rolled thread, there is some cold working of the material resulting in grain alignment within the material which also contributes to enhanced strength and fatigue properties.

If you have any questions about custom U-Bolts or would like to discuss your specific U-Bolt needs, please feel free to give us a call.